Tasked with re-engineering a motorized product, I chose the rotary tattoo machine due to the stark contrasts between rotary and coil machines.

While coil machines excel in lining, shading, adjustability, and control, rotary machines gained popularity for their lightweight design, quiet operation, and low maintenance.

Motivated to create the best rotary machine possible, InkOptima merges the benefits of both coils & rotaries, in an ergonomic, multi-grip handle.

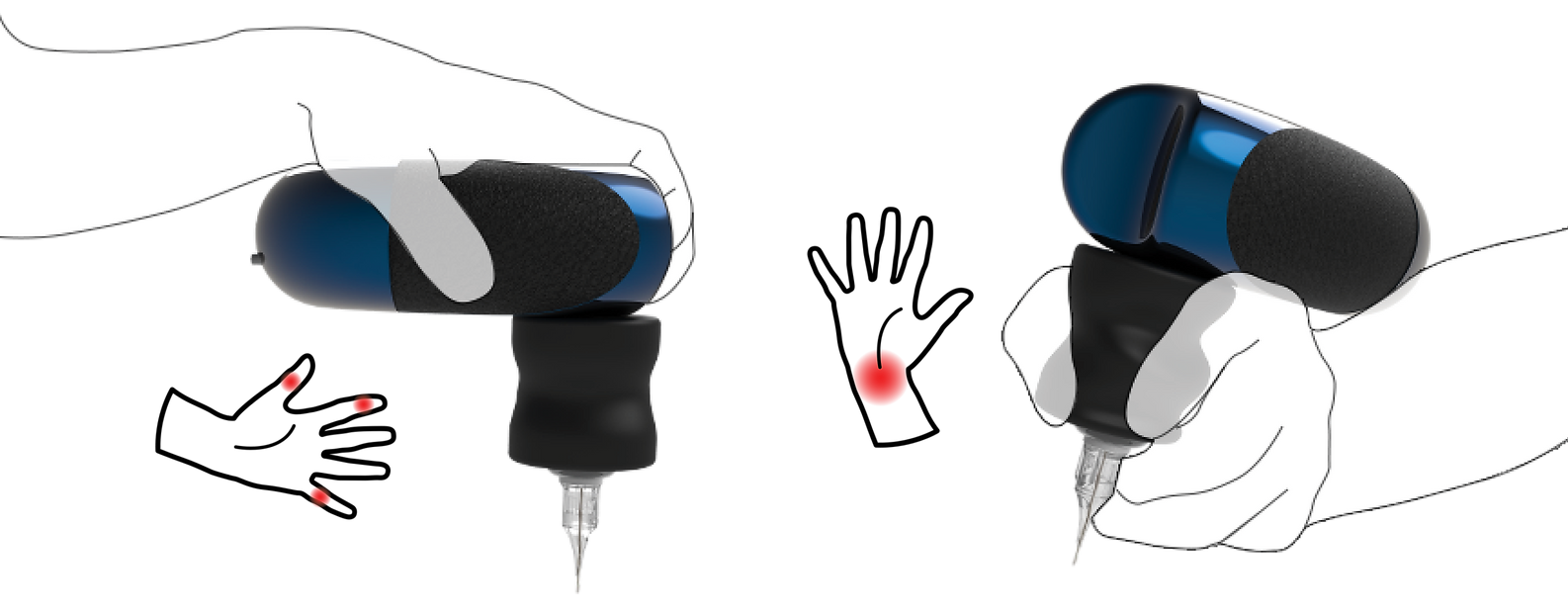

Top Grip

Bottom Grip

In longer tattoo sessions, or for lesser-abled artists, top grip relieves pressure points in fingers.

Bottom, or traditional grip relieves pressure points in the wrist & allows more detailed movement.

Grip Options

Traditional Grip

Personalized EVA Grip

Artist Takeaway

“I don’t use rotaries because the lack of adjustability. I want to put out the best tattoo possible”

- Interviewee

.png)

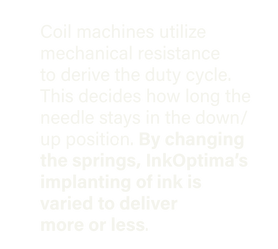

Introducing Spring-Duty Optimization

Springs vary the direct drive's timing, so the user can optimize the duty cycle

1.5" LED Display

Control Board:

-

-/+ Voltage

-

On/Off Ctrl

-

Screen mode

-

Light Ctrl

Power source incorporated into handle; InkOptima inherently has a low center of gravity & easy control

Components & Manufacturing

Internals View

Physical Model

Through the Journey...

Ergonomic Quick Models

Lines & shading mock ups were presented to users to trace using a Play-Dough handle, molded to their preference.

Notes:

-

Very few similarities between study models; making mass manufacturing difficult

-

Righties & lefty handles must differ handles

-

Play-Dough made creating comfortable, unique grips quick & accessible

Inspired by the custom study models, I was led to incorporate InkOptima's personalized grip, utilizing soft, thermo-moldable ethylene vinyl acetate (EVA).

Concepts & Ideation