SerpiSense

A smart jacket for temperature regulation.

***batteries not included***

Fall 2023 - 60 hours - Individual

Exhibited in Fusion on First, Phoenix, AZ

Street Level Gallery

Brief:

Tasked with developing wearable technology, I designed outerwear that adapts to the user's environment.

Rather than requiring the addition or removal of layers or the manual activation of heating, cooling, or fan components, SERPISENSE intelligently responds to temperature changes—insulating or increasing conductivity based on the user's comfort preferences

Reflective Polyester

to reflect light & heat when in warmer areas

Rip-stop Nylon

for water resistance, durability & breathability

Broadcloth Cotton

for a soft & strong inner liner

Thermochromic PU

to visually denote rapid changes in temperature

Secured closure with #10 22" silver zipper.

Face guard easily snaps with discreet magnets.

How it Works:

An inflation unit takes air from inside the jacket; the user's comfortable microclimate, to insulate the unit at varying rates using a coded circuit playground, vacuum DC motors, mosfets & battery packs.

With these, insulation is automatically adjusted based on the environments temperature, however, living in Arizona & without access to walk in freezers, the code was tough, if not impossible, to test. For proof of inflation concept, a consistent rate was utilized, yet more prototyping will be done moving forward.

Through the Process...

How has temperature-regulated clothing been done before?

What else out there can improve temperature regulated clothing?

To regulate maximum body temperature while considering cost & timeline, I chose to utilize multiple methods to regulate:

-

Bigger outerwear silhouette

-

Radiation blocking fabrics

-

Air inflation

Tech/CMF Board

Outerwear Board

Initial Concept

Since SERPISENSE inflates to comfort the user, the jacket should also be styled with the poise & flair of nature's inflation techniques.

The forms of arachnids, mantises, bears, peacocks, and plants like cacti were studied to model the pattern after, but the cobra snake's expanding hood was moved forward with due to the most reproducible similarities in form.

Initial Prototypes

Once the muslin prototype for the liner was completed in a size large, the next steps were to test the inflatable.

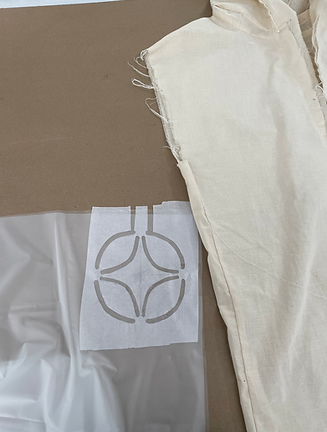

Using wax paper sandwiched and fused between thermoplastic polyurethane shower liners, I was able to create 2D patterns that would inflate to create the insulated puffer part of the jacket. This proved time consuming with drawing the pattern and hand cutting; luckily, I made a stencil, yet it was not perfect.

Inflatable Development

While the wax paper enabled the construction of the inflatable, it gave it a crinkly texture and sound when deflated. Though it was somewhat muted due to the TPU, it wasn't an user-friendly feature.

Using a CNC laser cutter made the cutouts way easier to achieve, yet prototypes with fabric middle layers proved unhelpful due to issues when fusing TPU sheets. Laser welding them on the out-of-focused bed proved really hopeful, yet ventilation maintenance and lack of access to the laser ruled it out as an option with the timeframe. Not to mention, TPU's toxicity when lasering.

The wax paper was moved forward with due to time but due to be changed. It was measured out to the liners dimensions +1.5" to account for the 3" of width of insulation it achieves when inflated.